- Shandong TUOBO Microwave Machinery Co.,Ltd.

- Providing users with easy-to-use equipment and services,the quality is the priority, the customer is

Home>Products>Injection Molding Equipment>8.3 - 18 G / S Injection Rate Caps / Handles Plastic Injection Molding Equipment

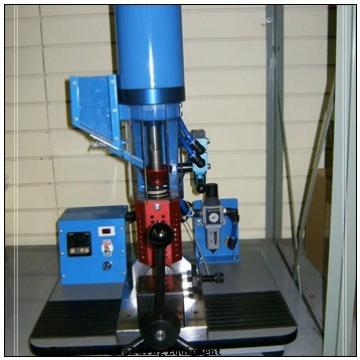

8.3 - 18 G / S Injection Rate Caps / Handles Plastic Injection Molding Equipment

- LD

LD_4800A

- Shandong

- 1set

- Negotiable

- 45 working days

- L/C, T/T, Western Union

- 10sets per month

-

Chen2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Chen2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Injection moulding machinery Adopting Europe technology,hydraulic unit adopts proportional pressure and flow control,the pressure and the speed can be adjusted,stable movement curve and gentle shock,the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to use. Close-loop PID temperature control with the advantage of high precision. The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators’s safety.

Mould Our mould producing center produces exact mould ,adopts the high grade material to make. The perform mould uses the hot runner technology, inside uses the imported steel, the surface’s brightness is very high and the service time is very long.

The design of equipment is logical, easily operation.

The automatic level is very high, the wage is very little.

Using famous imported hydraulic, electrical, sealing parts, the trouble is low.

No matter what the product’s outside or inside, they can get the best guarantee, the good products rate can be above 99%.

A. Injection Unit

•A07) Oil temperature indication

•A08) Adjustable such back before and after refilling

•A09) Auto sprue break

•A10) Linear transducer to control programmable injection position

•A11) Cold start screw prevention

•A12) Sliding Mechanism for hopper

•A13) Gas Nitrated hardened screw and Barrel

•A14) Screw back pressure con troll with pressure relief valve

•A15) Hand Operated Lubrication Unit

B. Clamping Unit

•B01) Five Point twin toggle locking system

•B02) Case Hardened toggle, Brackets and links with hardened PIN & BUSH

•B03) Motorized mould height adjustment for quick mould change

•B04) Auto tonnage setting facility

•B05) Low pressure precise mould protection with pressure and time setting

•B06) Five stage Mould closing

•B07) Five stage Mould opening

•B08) Hydraulic cushioning for consistent mould opening position

•B09) Linear transducer to control programmable clamp system

•B10) Electrical and hydraulic (Dump value) interlock safety gate

•B11) Moving platen with mechanical support with Teflon

•B12) Hydraulic Ejector with Multi stroke

•B13) Auto lubrication unit

C. Ejector

•C01) Linear transducer to control programmable ejector position

•C02) Multiple stroke ejection

•C03) Ejector forward/ backward speed adjustable

•C04) Ejector forward/ backward pressure adjustable

•C05) Two stage in ejector forward/ backward operation

•C06) Additional safety of sensing ejector backward position with proximity switch

Structure principle during actual working status,the system directly feedbacks the pressure-flow rate singal through exit pressure sensor of oil pump and cycloscope to the high speed servo driver.The servo driver gives out electric signal to servo driving motor and oil pump,allowing of corresponding change to pressure and flow rate,therefore,theclosed clrcuit control of pressure and flow rate is realized.

Overall execution GB22530-2008”Rubber plastic injection molding machine safety requirements”standard(safety,reliability),fully meet the technical requirements of exporting European countries.

Contact Us

- Shandong TUOBO Microwave Machinery Co.,Ltd.

- Email[email protected]

- AddressTianqiao District, Jinan, Shandong, China

- Phone(Working Time)

- WhatsApp+8618660125156

Product Categories

New Products

LD-300 Model of Bottle Injection Molding Equipment

LD-300 Model of Bottle Injection Molding Equipment Mini 38kw Injection Molding Machine / Plastic Injection Molding Equipment

Mini 38kw Injection Molding Machine / Plastic Injection Molding Equipment 68 ton High Speed Plastic Injection Molding Equipment / Plastic Bucket Making Machine

68 ton High Speed Plastic Injection Molding Equipment / Plastic Bucket Making Machine 8.3 - 18 G / S Injection Rate Caps / Handles Plastic Injection Molding Equipment

8.3 - 18 G / S Injection Rate Caps / Handles Plastic Injection Molding Equipment 150 Ton Oral liquid plastic bottle ISB50 injection blow moulding machine

150 Ton Oral liquid plastic bottle ISB50 injection blow moulding machine